The Rise of China CNC Precision Turning Parts Factory: A Catalyst for Global Manufacturing

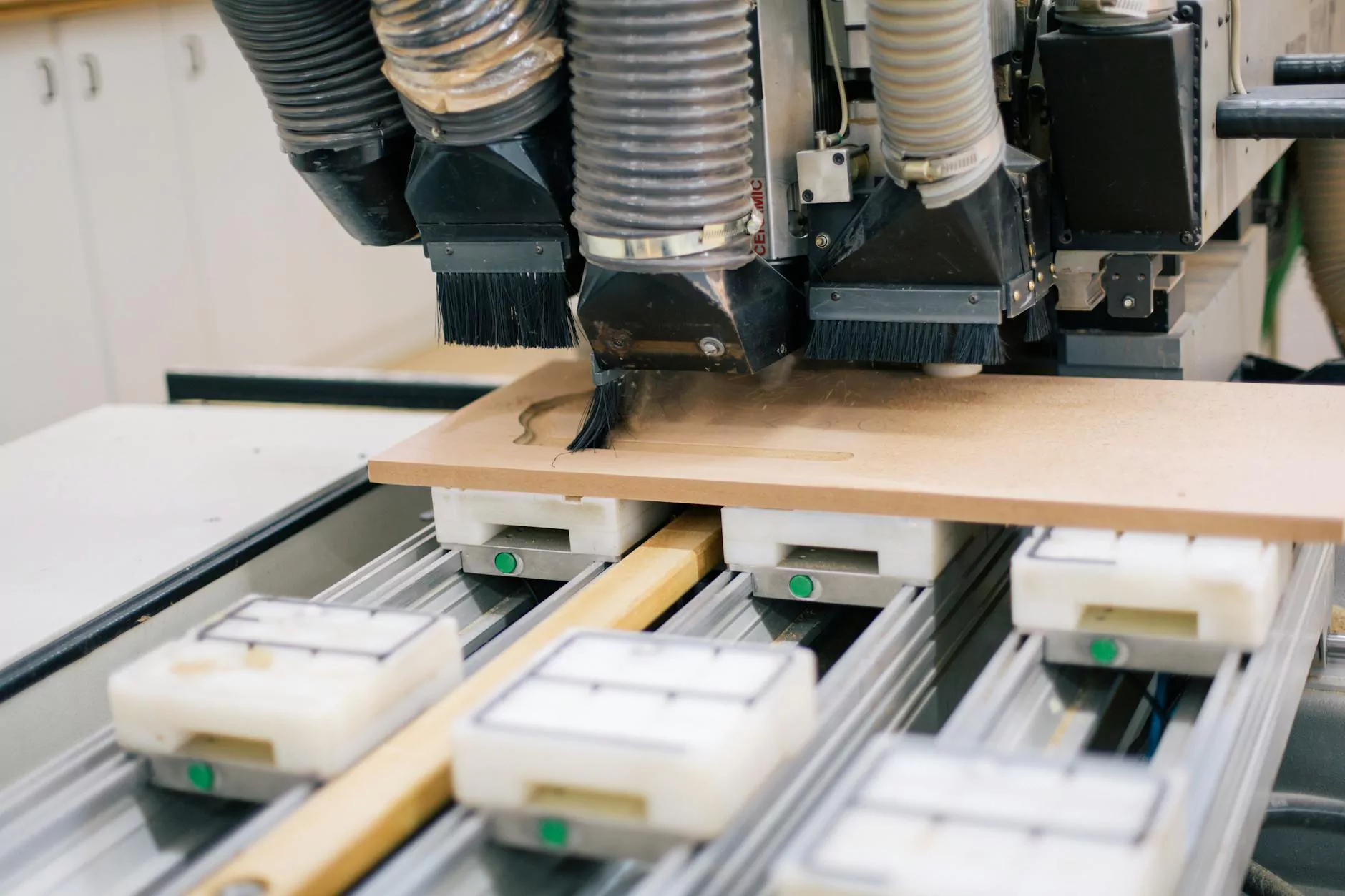

China CNC precision turning parts factory has emerged as a pivotal player in the global manufacturing landscape. The precision and advanced technology used in these factories play a crucial role in meeting the diverse demands of various industries. This article delves deep into the significance, operational methodologies, and benefits of CNC precision turning parts in modern manufacturing.

The Significance of CNC Precision Turning Parts in Manufacturing

CNC (Computer Numerical Control) precision turning parts are integral to the production of high-quality components used in many sectors including automotive, aerospace, electronics, and medical devices. The significance of these parts can be summarized as follows:

- Accuracy: CNC machines provide unmatched precision, ensuring that parts meet stringent specifications.

- Efficiency: The efficiency of CNC machining processes reduces wasted material and time.

- Versatility: CNC machinery can produce complex geometries that manual processes cannot achieve.

- Cost-Effectiveness: Higher production rates lead to lower per-unit costs, making it a viable option for mass production.

The Advanced Techniques Employed in CNC Precision Turning

The techniques employed in CNC precision turning are continually evolving, driven by the need for innovation and efficiency. Some of the most noteworthy techniques include:

1. Multi-Axis Turning

This technique enables the machining of complex parts by allowing the tool to move in multiple directions, increasing the accuracy and reducing production times.

2. Live Tooling

Live tooling incorporates rotating tools into CNC lathes, allowing for more complex shapes and reduced cycle times.

3. CAD/CAM Integration

Utilizing CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software improves design precision and streamlines the machining process.

Quality Control in CNC Precision Turning Parts

Quality is paramount in the production of CNC precision turning parts. Chinese factories have adopted rigorous quality control measures, ensuring that every part meets exact specifications.

1. Inspection Procedures

Quality control begins with raw materials. Advanced inspection techniques, such as Coordinate Measuring Machines (CMM), are employed to verify dimensions and tolerances.

2. Certifications and Standards

Many Chinese CNC precision turning parts manufacturers comply with international standards such as ISO 9001, which attests to their commitment to quality management systems.

The Competitive Advantages of Working with China CNC Precision Turning Parts Factory

Choosing a China CNC precision turning parts factory provides numerous competitive advantages for companies looking to enhance their manufacturing capabilities:

- Cost Savings: Labor and material costs in China are often lower, resulting in substantial savings for overseas companies.

- Rapid Production Times: Advanced machinery allows for faster turnaround times without compromising quality.

- Access to Expertise: With years of experience, Chinese manufacturers offer unparalleled knowledge and expertise in CNC machining technologies.

- Scalability: Factories can easily scale production up or down based on demand, providing flexibility to clients.

Applications of CNC Precision Turning Parts in Various Industries

CNC precision turning parts find applications in various industries, making them indispensable in the production ecosystem. Here’s a closer look at the sectors that benefit from these intricately manufactured components:

1. Automotive Industry

The automotive industry relies heavily on precision turning parts for components such as gears, shafts, and brackets. High precision enables manufacturers to enhance vehicle performance and safety.

2. Aerospace Sector

In aerospace, the demand for lightweight and strong components is critical. CNC machining techniques ensure that the parts are not only accurate but also durable enough to withstand extreme conditions.

3. Medical Devices

Precision parts are vital for the production of medical devices where even the smallest error can lead to serious consequences. China’s CNC precision turning parts factories produce components that meet stringent medical standards.

4. Electronics Manufacturing

Electronic components often require complex shapes and precise measurements, making CNC precision turning essential for the production of housings, connectors, and other device parts.

Future Trends in CNC Precision Turning Parts Industry

The CNC precision turning parts industry is poised for continued growth and innovation. Key trends shaping the future include:

1. Automation and Smart Manufacturing

As industries adopt Industry 4.0 technologies, automating CNC processes will lead to greater efficiencies and precision.

2. Sustainable Practices

With growing environmental concerns, manufacturers are increasingly focusing on sustainable practices, including waste reduction and energy efficiency.

3. Customization

As market demands shift towards personalized products, CNC precision turning factories will adapt by offering greater customization options.

Conclusion: The Vital Role of China CNC Precision Turning Parts Factory in Global Manufacturing

The impact of China CNC precision turning parts factory on global manufacturing cannot be overstated. Through advanced technology, rigorous quality control, and cost-effectiveness, these factories have positioned themselves as leaders in the field. As industries continue to evolve, the adaptability and innovation of CNC precision turning will play a critical role in shaping the future of manufacturing.

In conclusion, understanding the importance and functionality of CNC precision turning parts is essential for businesses aiming to stay competitive. By partnering with a reliable Chinese manufacturer, companies can ensure high-quality components that drive productivity and innovation.

Call to Action

If you're in need of high-quality CNC precision turning parts, consider reaching out to DeepMould. Our commitment to excellence in the fabrication of precision parts can help elevate your manufacturing processes.